Lina Paola Pardo Quevedo

MemberForum Replies Created

-

Yes, that’s correct. Biosecurity is the cornerstone of poultry disease control, and if biosecurity measures are missed, it significantly increases the risk of disease introduction and spread, making prevention efforts less effective, according to poultry experts. Biosecurity is the primary line of defense in preventing disease outbreaks in poultry farms.

-

The bottom Line of Poultry Disease control is Biosecurity if it is missed to Prevention

-

Muhammad Ahmad

MemberAugust 12, 2025 at 4:48 pm in reply to: Composite vs. Individual Sampling for Quality AnalysisThanks

-

The most important stage of feed formulation is accurately determining the nutrient requirements of the animal.

Feed formulation is a complex process that involves creating a balanced diet for livestock and other animals to ensure they receive all the necessary nutrients for optimal health, growth, and production. While other steps like selecting ingredients and calculating costs are crucial, they all depend on a precise understanding of the animal’s needs.

Here’s why this stage is the most critical:

* Foundation of the Diet: The animal’s nutrient requirements form the very foundation of the entire formulation process. You can’t select the right ingredients or balance the diet without knowing what the animal needs in terms of protein, energy, vitamins, and minerals.

* Species, Age, and Production Goals: Nutrient needs are not one-size-fits-all. They vary dramatically based on:

* Species: A dairy cow has very different needs than a broiler chicken or a fish.

* Age and life stage: A young, growing animal requires different nutrients than a mature animal or a breeding animal.

* Production goals: An animal raised for meat production needs a different diet than one raised for milk or egg production.

* Economic and Performance Implications: A mistake in this initial stage can lead to a formulation that is either nutritionally deficient or unnecessarily expensive.

* Deficient Diet: If the diet doesn’t meet the animal’s needs, it can lead to poor growth, health problems, and reduced production (e.g., lower milk or egg yield).

* Over-fortified Diet: Including too many nutrients can be wasteful and increase feed costs, which are a major expense in animal production.

In essence, the other stages of feed formulation—like ingredient selection, cost-optimization, and quality control—are all steps to ensure that the final feed successfully meets the nutritional requirements that were defined in the first and most important stage.The most important stage of feed formulation is accurately determining the nutrient requirements of the animal.

Feed formulation is a complex process that involves creating a balanced diet for livestock and other animals to ensure they receive all the necessary nutrients for optimal health, growth, and production. While other steps like selecting ingredients and calculating costs are crucial, they all depend on a precise understanding of the animal’s needs.

Here’s why this stage is the most critical:

* Foundation of the Diet: The animal’s nutrient requirements form the very foundation of the entire formulation process. You can’t select the right ingredients or balance the diet without knowing what the animal needs in terms of protein, energy, vitamins, and minerals.

* Species, Age, and Production Goals: Nutrient needs are not one-size-fits-all. They vary dramatically based on:

* Species: A dairy cow has very different needs than a broiler chicken or a fish.

* Age and life stage: A young, growing animal requires different nutrients than a mature animal or a breeding animal.

* Production goals: An animal raised for meat production needs a different diet than one raised for milk or egg production.

* Economic and Performance Implications: A mistake in this initial stage can lead to a formulation that is either nutritionally deficient or unnecessarily expensive.

* Deficient Diet: If the diet doesn’t meet the animal’s needs, it can lead to poor growth, health problems, and reduced production (e.g., lower milk or egg yield).

* Over-fortified Diet: Including too many nutrients can be wasteful and increase feed costs, which are a major expense in animal production.

In essence, the other stages of feed formulation—like ingredient selection, cost-optimization, and quality control—are all steps to ensure that the final feed successfully meets the nutritional requirements that were defined in the first and most important stage. -

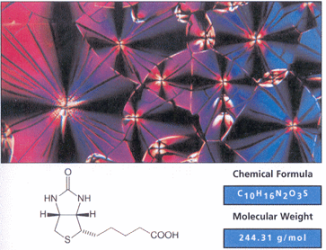

🧬 Biotin (Vitamin H) – Comprehensive Overview

🧪 Nomenclature & Chemical Nature

Alternative Names:

Vitamin H

Vitamin B7 (most accurate)

Vitamin B8 (sometimes used, though B8 often refers to inositol)

Coenzyme R

Factor W

Chemical Profile:

A sulfur-containing organic acid

Colorless, odorless, crystalline compound

Water-soluble vitamin

Functions as a coenzyme in carboxylation reactions

🎯 Target Species & Production Categories

Biotin is essential across a wide range of species and production stages:

Ruminants: Calves, high-yielding dairy cows, lactating sheep

Poultry: Broilers, breeders, layers, turkeys, geese, pheasants

Swine: Growers, finishers, breeders

Equines: Performance and working horses

Canines: Companion and working dogs

Fish: Trout, carp

Others: High-performance or stressed animals across categories

⚙️ Biological Functions

Energy Metabolism: Coenzyme for carboxylase enzymes involved in gluconeogenesis, fatty acid synthesis, and amino acid catabolism

Skin & Hoof Health: Vital for keratin synthesis; supports epidermal tissue integrity, hair growth, and hoof horn quality

Reproductive Health: Supports fertility and embryonic development

Bone Development: Contributes to skeletal growth and maintenance

🌾 Natural Sources & Bioavailability

Rich Sources:

Brewer’s yeast, distillers grains, oilseed meals (e.g., soybean, canola), liver extract, blackstrap molasses, maize gluten feed, alfalfa (lucerne) meal, dried skim milk

Medium Sources:

Fresh vegetables, select fruits

Poor Sources:

Cereals (e.g., wheat, maize), meat, fish

Bioavailability Notes:

Exists in both free and bound forms; bound biotin is poorly available to monogastrics

Bioavailability ranges from 5% (e.g., wheat) to 75% depending on feed type

Synthesized by intestinal microflora (caecum/colon in monogastrics; rumen in ruminants)

Feed biotin levels vary with crop variety, season, yield, and storage

🚨 Deficiency Symptoms by Species

🧍 General Signs (Across Species)

Reduced growth rate and feed conversion

Dermatitis and skin inflammation

Cracked hooves, soles, beaks, and horns

Alopecia (hair/feather loss)

Inflammation of mouth mucosa

Fertility disorders and poor reproductive performance

🐓 Poultry

Poor growth and feed efficiency

Leg and beak deformities

Poor plumage and skin condition

Lesions on feet, beak, and eyes

Leg weakness, hock disorders

Chondrodystrophy: Shortened long bones

Perosis: Enlarged, deformed hock joints

Poor egg production and hatchability

Fatty Liver and Kidney Syndrome: Especially on low-fat diets

🐄 Ruminants

Calves: Hair loss, hoof cracks, sole erosion, reduced growth; severe cases may show hind leg paralysis

Adults (high yield/stress): Brittle horns, poor hoof horn quality

Typically synthesize enough biotin via rumen microbes, but supplementation may be needed under stress or high production

🐖 Pigs

Scaly skin, ulcers

Hair loss

Sole lesions, lameness

Hind leg spasticity

Poor fertility, delayed estrus, reduced conception rates

🐕 Dogs

Poor coat condition

Hair loss, scaly skin

Dermatitis

🐎 Horses

Weak hoof horn, especially at lower edges

Prone to damage at hoof walls, soles, and white line junction

🐟 Fish

Many species synthesize biotin via intestinal microflora

Deficiency signs:

Anorexia

Reduced growth and feed conversion

Increased mortality

Trout: Susceptible to blue slime disease

-

Canola meal is the most preferred among the three for poultry. It’s derived from low-erucic, low-glucosinolate rapeseed varieties and offers around 36–38% crude protein. Its amino acid profile—especially lysine and methionine—is decent, and digestibility is high when diets are formulated on a digestible amino acid basis. It’s commonly included in broiler diets.

Rapeseed meal, from traditional varieties, has similar protein levels but higher anti-nutritional factors like erucic acid and glucosinolates. These can impair thyroid function and reduce feed intake. If using rapeseed meal, ensure it’s from “double-zero” varieties (low erucic and low glucosinolate) to make it safer and more digestible.

Mustard meal is less common in poultry feed due to its pungent taste and high glucosinolate content, which can reduce palatability and performance. It may be used in small amounts or after detoxification, especially in regions where mustard is locally abundant.

In short:

-

Use canola meal confidently in poultry diets.

-

Use rapeseed meal only if it’s a low-toxin variety.

-

Use mustard meal cautiously and in limited amounts.

-

-

Biosecurity measures must be in place.

-

Traceability can be done through record keeping, beginning from receiving ingredients to batching records. Can as well be recalled through customers, who already have faulty batches.

-

General recommendations to maintain product quality and efficacy during storage include the following, but refer to the label for product-specific recommendations:

Temperature – store in a cool environment, ideally below 25°C. Some products may require air conditioning or refrigeration to maintain potency.

Vitamins such as ascorbic acid (vitamin C) are especially unstable and require cool storage below 20°C to maintain efficacy.

Being protein-based, enzymes denature and lose biological activity when exposed to high temperatures. Heat reduces their effectiveness substantially during storage and processing unless specially protected by encapsulation or coating.

Humidity – maintain low humidity levels (ideally <60%) to keep products dry and prevent caking, or chemical breakdown. Use sealed containers to protect from moisture penetration. Store off the ground on pallets or shelves to protect from moisture penetration.

Light Protection – some products, such as vitamins are light-sensitive, requiring storage in opaque or light-resistant containers and away from direct sunlight.

Inventory Management – follow first-in-first-out (FIFO) or first-expiry-first-out (FEFO) systems to ensure older stock is used before newer stock, minimizing expiry or spoilage risk.

-

How can feed manufacturers implement sustainable sourcing practices for ingredients

-

Bello Bashir

MemberAugust 12, 2025 at 12:06 pm in reply to: Storage Conditions for Vitamins and Medications59 – 77 degrees Celsius

-

Following Good and Standard Medication Practices.