Lina Paola Pardo Quevedo

MemberForum Replies Created

-

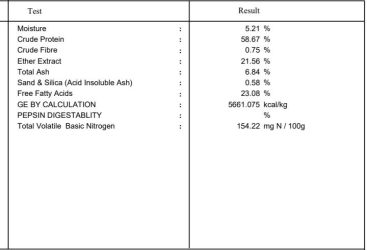

Based on the nutritional analysis you provided, your observation is correct and a very important one. It is a sign of a significant quality issue in the feed ingredient.

Here is an explanation of why the Free Fatty Acid (FFA) content is higher than the Ether Extract (EE) content:

1. What are Ether Extract (EE) and Free Fatty Acids (FFA)?

* Ether Extract (EE): This is the traditional method for measuring the total fat content in a feed. It essentially measures everything in the sample that is soluble in a solvent like ethyl ether. The result primarily includes triglycerides (the main form of fat) but can also contain other fat-soluble compounds. It is often referred to as “crude fat.”

* Free Fatty Acids (FFA): This analysis specifically measures the amount of fatty acids that are “free” or unattached to a glycerol backbone. Healthy, fresh fats consist mostly of triglycerides. Free fatty acids are produced when these triglycerides are broken down.

2. The Relationship in a Healthy Sample

In a fresh, high-quality sample of fat or a fat-rich ingredient, the vast majority of the fat is in the form of triglycerides. Therefore, the EE value would be significantly higher than the FFA value, as the FFA content would be very low.

3. Why is FFA Higher than EE in Your Sample?

The result where FFA (23.08%) is higher than EE (21.56%) is a strong indicator of spoilage or rancidity. Here’s what likely happened:

* Hydrolysis: The triglycerides in the ingredient have been broken down, or hydrolyzed, into free fatty acids and glycerol. This process is accelerated by heat, moisture, and enzymes produced by microorganisms.

* Methodological Difference: The Ether Extract method is an older technique that can sometimes underestimate the total lipid content, especially if the sample has undergone significant degradation. The FFA analysis, however, directly measures the product of this degradation.

* Indication of Quality: The very high FFA value indicates that a large portion of the fat in the sample has become rancid. This not only makes the fat less digestible for the animal but also negatively impacts the palatability of the feed and can lead to health problems. The rancid fats can create compounds that destroy vitamins, damage cells, and are unpalatable to animals.

In conclusion, the analysis you provided points to a feed ingredient that is of poor quality. It has likely been stored improperly, leading to a breakdown of its fat content. The result is a high concentration of free fatty acids, a strong signal of a rancid product that may be unsuitable for high-quality feed formulation.Based on the nutritional analysis you provided, your observation is correct and a very important one. It is a sign of a significant quality issue in the feed ingredient.

Here is an explanation of why the Free Fatty Acid (FFA) content is higher than the Ether Extract (EE) content:

1. What are Ether Extract (EE) and Free Fatty Acids (FFA)?

* Ether Extract (EE): This is the traditional method for measuring the total fat content in a feed. It essentially measures everything in the sample that is soluble in a solvent like ethyl ether. The result primarily includes triglycerides (the main form of fat) but can also contain other fat-soluble compounds. It is often referred to as “crude fat.”

* Free Fatty Acids (FFA): This analysis specifically measures the amount of fatty acids that are “free” or unattached to a glycerol backbone. Healthy, fresh fats consist mostly of triglycerides. Free fatty acids are produced when these triglycerides are broken down.

2. The Relationship in a Healthy Sample

In a fresh, high-quality sample of fat or a fat-rich ingredient, the vast majority of the fat is in the form of triglycerides. Therefore, the EE value would be significantly higher than the FFA value, as the FFA content would be very low.

3. Why is FFA Higher than EE in Your Sample?

The result where FFA (23.08%) is higher than EE (21.56%) is a strong indicator of spoilage or rancidity. Here’s what likely happened:

* Hydrolysis: The triglycerides in the ingredient have been broken down, or hydrolyzed, into free fatty acids and glycerol. This process is accelerated by heat, moisture, and enzymes produced by microorganisms.

* Methodological Difference: The Ether Extract method is an older technique that can sometimes underestimate the total lipid content, especially if the sample has undergone significant degradation. The FFA analysis, however, directly measures the product of this degradation.

* Indication of Quality: The very high FFA value indicates that a large portion of the fat in the sample has become rancid. This not only makes the fat less digestible for the animal but also negatively impacts the palatability of the feed and can lead to health problems. The rancid fats can create compounds that destroy vitamins, damage cells, and are unpalatable to animals.

In conclusion, the analysis you provided points to a feed ingredient that is of poor quality. It has likely been stored improperly, leading to a breakdown of its fat content. The result is a high concentration of free fatty acids, a strong signal of a rancid product that may be unsuitable for high-quality feed formulation. -

Thank you everyone for your inputs.

-

Please refer to the picture below showing analysis of feed ingredients. Can someone explain how FFA content is higher than EE? All explanations are welcome.

-

Standardisation of phytochemicals is a big hindrance to its use and obtaining its desried effect. The level of active ingredients in the source varies according to age, season, rearing practice, extratction technique. It is quite difficult to obtain the same level of active ingredient at all times. But phytoactives are an excellent way that can promote antibiotic free rearing of livestock.

-

Energy-efficient motors in feed mills reduce power consumption, lower operating costs, minimize heat generation, improve reliability, and extend equipment lifespan while supporting environmental sustainability.

-

Delivery trucks play a significant and often overlooked role in the spread of feed-borne diseases. They act as fomites, which are inanimate objects that can carry infectious agents from one place to another. While the feed itself might be a source of contamination, the vehicles that transport it can be a major vector for cross-contamination between farms and feed mills.

Here are the key roles delivery trucks play in the spread of feed-borne diseases:

1. Cross-Contamination from Previous Loads

A truck that has previously delivered feed to an infected farm can carry pathogens on its exterior, interior, or even in residual feed dust. If the vehicle is not properly cleaned and disinfected before its next trip, it can transfer these pathogens to a new, healthy farm. This is a critical point of failure in biosecurity, as a single truck can connect multiple farms and a feed mill, creating a chain of potential transmission.

2. Physical Contamination from the Environment

The tires, wheel wells, and undercarriage of a delivery truck can pick up contaminated material like manure, soil, or dust from one farm’s premises. This material, which can contain bacteria like Salmonella and viruses like Porcine Epidemic Diarrhea virus (PEDV), can then be deposited at the next farm the truck visits.

3. Contamination of the Feed Itself

While the feed mill is the primary source of the feed, the truck itself can contaminate the product during transport.

* Residual Contamination: If the truck’s hopper or a bulk tank is not thoroughly cleaned, feed dust or residue from a previous contaminated batch can mix with a new, clean batch.

* Environmental Contamination: A poorly sealed truck can allow outside contaminants, such as feces from wild birds or rodents, to enter and contaminate the feed.

4. Human-Mediated Transmission

The truck driver and their equipment can also be a source of transmission. The driver can inadvertently track pathogens from a farm into the truck’s cab on their boots or clothing. If they don’t follow strict biosecurity protocols, they can then carry these pathogens from the cab to other locations or transfer them to the next farm they visit. This is why some biosecurity protocols require drivers to wear farm-specific protective gear and to clean the truck’s cab.

5. Role in Disease Outbreak Dynamics

Research has shown that indirect transmission routes via delivery trucks can have an immense impact on the speed and scale of disease spread. In fact, some studies have estimated that a significant percentage of new infections in livestock operations can be traced back to contaminated vehicles. This highlights why biosecurity measures focused on vehicle sanitation are so critical.

To mitigate this risk, modern biosecurity protocols for feed delivery often include:

* Route Scheduling: Planning delivery routes to visit high-risk or infected farms last, with a thorough cleaning and disinfection process before returning to high-health sites.

* Vehicle Sanitation: Regular and rigorous washing, disinfecting, and drying of the truck’s exterior and interior, including the cab.

* On-Farm Protocols: Implementing biosecurity measures at the farm gate, such as dedicated driveways for feed trucks, wheel washes, and strict rules for drivers and their footwear.Delivery trucks play a significant and often overlooked role in the spread of feed-borne diseases. They act as fomites, which are inanimate objects that can carry infectious agents from one place to another. While the feed itself might be a source of contamination, the vehicles that transport it can be a major vector for cross-contamination between farms and feed mills.

Here are the key roles delivery trucks play in the spread of feed-borne diseases:

1. Cross-Contamination from Previous Loads

A truck that has previously delivered feed to an infected farm can carry pathogens on its exterior, interior, or even in residual feed dust. If the vehicle is not properly cleaned and disinfected before its next trip, it can transfer these pathogens to a new, healthy farm. This is a critical point of failure in biosecurity, as a single truck can connect multiple farms and a feed mill, creating a chain of potential transmission.

2. Physical Contamination from the Environment

The tires, wheel wells, and undercarriage of a delivery truck can pick up contaminated material like manure, soil, or dust from one farm’s premises. This material, which can contain bacteria like Salmonella and viruses like Porcine Epidemic Diarrhea virus (PEDV), can then be deposited at the next farm the truck visits.

3. Contamination of the Feed Itself

While the feed mill is the primary source of the feed, the truck itself can contaminate the product during transport.

* Residual Contamination: If the truck’s hopper or a bulk tank is not thoroughly cleaned, feed dust or residue from a previous contaminated batch can mix with a new, clean batch.

* Environmental Contamination: A poorly sealed truck can allow outside contaminants, such as feces from wild birds or rodents, to enter and contaminate the feed.

4. Human-Mediated Transmission

The truck driver and their equipment can also be a source of transmission. The driver can inadvertently track pathogens from a farm into the truck’s cab on their boots or clothing. If they don’t follow strict biosecurity protocols, they can then carry these pathogens from the cab to other locations or transfer them to the next farm they visit. This is why some biosecurity protocols require drivers to wear farm-specific protective gear and to clean the truck’s cab.

5. Role in Disease Outbreak Dynamics

Research has shown that indirect transmission routes via delivery trucks can have an immense impact on the speed and scale of disease spread. In fact, some studies have estimated that a significant percentage of new infections in livestock operations can be traced back to contaminated vehicles. This highlights why biosecurity measures focused on vehicle sanitation are so critical.

To mitigate this risk, modern biosecurity protocols for feed delivery often include:

* Route Scheduling: Planning delivery routes to visit high-risk or infected farms last, with a thorough cleaning and disinfection process before returning to high-health sites.

* Vehicle Sanitation: Regular and rigorous washing, disinfecting, and drying of the truck’s exterior and interior, including the cab.

* On-Farm Protocols: Implementing biosecurity measures at the farm gate, such as dedicated driveways for feed trucks, wheel washes, and strict rules for drivers and their footwear. -

Mandatory pathogen testing for every batch of feed is not a standard regulatory practice. The primary approach is a preventative, risk-based system called HACCP (Hazard Analysis and Critical Control Points).

* Pros of Mandatory Testing: Increased public health safety, reduced outbreaks, and enhanced consumer confidence.

* Cons of Mandatory Testing: Extremely high cost, logistical challenges, the limitations of sampling (can miss contamination), and a reactive focus on end-products rather than proactive prevention.

The current consensus is that a robust preventative system like HACCP is more effective and sustainable than testing every single batch.Mandatory pathogen testing for every batch of feed is not a standard regulatory practice. The primary approach is a preventative, risk-based system called HACCP (Hazard Analysis and Critical Control Points).

* Pros of Mandatory Testing: Increased public health safety, reduced outbreaks, and enhanced consumer confidence.

* Cons of Mandatory Testing: Extremely high cost, logistical challenges, the limitations of sampling (can miss contamination), and a reactive focus on end-products rather than proactive prevention.

The current consensus is that a robust preventative system like HACCP is more effective and sustainable than testing every single batch. -

Mandatory pathogen testing for all feed batches can improve safety but may be costly

-

very helpful.