Msuega Clifford

MemberForum Replies Created

-

Ways to mitigate heat stress in broilers fall into three main categories: Environmental Management (Housing), Water/Electrolyte Management, and Nutritional Adjustments. The goal is to maximize heat loss and minimize the bird’s own heat production.

1. Environmental Management (Housing and Airflow) 🏠

These methods focus on reducing the temperature inside the poultry house and increasing the bird’s ability to cool itself via convection and evaporation.

* Ventilation and Airflow:

* Increase Air Speed: Use tunnel ventilation (in closed houses) and circulation fans to create a strong “wind-chill” effect over the birds. This increases heat loss via convection.

* Optimize Fans: Ensure exhaust fans are running at full capacity and all inlets/outlets are functioning to achieve frequent air exchange (replacing hot, humid air with cooler outside air).

* Cooling Systems:

* Evaporative Cooling: Install cooling pads (cool cells) or fogging/misting systems to lower the temperature of the incoming air. As water evaporates, it draws heat out of the air.

* Insulation and Reflection:

* Insulate Roofs and Walls: Good insulation prevents heat from the sun from radiating into the house.

* Reflective Surfaces: Paint the roof white or use reflective coatings to deflect solar radiation.

* Reduce Stocking Density: Lower the number of birds per square meter to reduce the total heat load produced by the flock and improve individual air access.

2. Water and Electrolyte Management 💧

Since broilers rely on panting (evaporative cooling) to dissipate heat, water is the single most critical nutrient during a heat wave.

* Provide Cool Water: Ensure birds have constant access to water that is as cool as possible. Flush water lines frequently during the hottest parts of the day to remove warm, stagnant water.

* Electrolyte Supplementation: Add electrolytes (salts of sodium, potassium, and chloride) to the drinking water. Panting causes the bird to exhale large amounts of carbon dioxide, disrupting the blood’s acid-base balance. Electrolytes help restore this balance, preventing dehydration and metabolic stress.

* Vitamin C (Ascorbic Acid): Supplementing the water or feed with Vitamin C helps maintain adrenal gland function and reduce the negative physiological effects of stress hormones.

3. Nutritional Adjustments 🥕

Dietary changes focus on reducing the “heat increment” (the heat generated by the bird’s body while digesting food) and ensuring nutrient intake is maintained despite reduced appetite.

* Shift Feeding Schedule: Feed birds during the cooler parts of the day (early morning and late evening) and restrict feed intake during peak heat hours. This allows them to digest when the ambient temperature is lower.

* Increase Nutrient Density: Since broilers eat less during heat stress, increase the concentration of key nutrients (energy and digestible amino acids) in the feed.

* Reduce Excess Protein: Lower the total level of crude protein in the feed and compensate with supplemental, synthetic limiting amino acids (like lysine and methionine). Digesting excess protein produces more metabolic heat (a higher heat increment) than digesting carbohydrates or fats.

* Increase Dietary Fat: Fat has the lowest heat increment of all major nutrients (protein, carbohydrates, and fat), making it a beneficial energy source during hot periods.Ways to mitigate heat stress in broilers fall into three main categories: Environmental Management (Housing), Water/Electrolyte Management, and Nutritional Adjustments. The goal is to maximize heat loss and minimize the bird’s own heat production.

1. Environmental Management (Housing and Airflow) 🏠

These methods focus on reducing the temperature inside the poultry house and increasing the bird’s ability to cool itself via convection and evaporation.

* Ventilation and Airflow:

* Increase Air Speed: Use tunnel ventilation (in closed houses) and circulation fans to create a strong “wind-chill” effect over the birds. This increases heat loss via convection.

* Optimize Fans: Ensure exhaust fans are running at full capacity and all inlets/outlets are functioning to achieve frequent air exchange (replacing hot, humid air with cooler outside air).

* Cooling Systems:

* Evaporative Cooling: Install cooling pads (cool cells) or fogging/misting systems to lower the temperature of the incoming air. As water evaporates, it draws heat out of the air.

* Insulation and Reflection:

* Insulate Roofs and Walls: Good insulation prevents heat from the sun from radiating into the house.

* Reflective Surfaces: Paint the roof white or use reflective coatings to deflect solar radiation.

* Reduce Stocking Density: Lower the number of birds per square meter to reduce the total heat load produced by the flock and improve individual air access.

2. Water and Electrolyte Management 💧

Since broilers rely on panting (evaporative cooling) to dissipate heat, water is the single most critical nutrient during a heat wave.

* Provide Cool Water: Ensure birds have constant access to water that is as cool as possible. Flush water lines frequently during the hottest parts of the day to remove warm, stagnant water.

* Electrolyte Supplementation: Add electrolytes (salts of sodium, potassium, and chloride) to the drinking water. Panting causes the bird to exhale large amounts of carbon dioxide, disrupting the blood’s acid-base balance. Electrolytes help restore this balance, preventing dehydration and metabolic stress.

* Vitamin C (Ascorbic Acid): Supplementing the water or feed with Vitamin C helps maintain adrenal gland function and reduce the negative physiological effects of stress hormones.

3. Nutritional Adjustments 🥕

Dietary changes focus on reducing the “heat increment” (the heat generated by the bird’s body while digesting food) and ensuring nutrient intake is maintained despite reduced appetite.

* Shift Feeding Schedule: Feed birds during the cooler parts of the day (early morning and late evening) and restrict feed intake during peak heat hours. This allows them to digest when the ambient temperature is lower.

* Increase Nutrient Density: Since broilers eat less during heat stress, increase the concentration of key nutrients (energy and digestible amino acids) in the feed.

* Reduce Excess Protein: Lower the total level of crude protein in the feed and compensate with supplemental, synthetic limiting amino acids (like lysine and methionine). Digesting excess protein produces more metabolic heat (a higher heat increment) than digesting carbohydrates or fats.

* Increase Dietary Fat: Fat has the lowest heat increment of all major nutrients (protein, carbohydrates, and fat), making it a beneficial energy source during hot periods. -

I have a feeding formula with a particular brand of feed that enables me to get above 2.5kg at 5 weeks

-

Olayiwola

MemberOctober 16, 2025 at 12:53 pm in reply to: Role & Importance of Smart Sensors, AI, IoT, & Mobile Dashboards in AquacultureThanks for the detailed explanation

-

Thanks, well detailed explanation

-

Excellent, thanks for the explanation

-

Good

Sharing knowledge

-

Nice sharing

-

Common <strong data-start=”7″ data-end=”27″>poultry diseases include <strong data-start=”36″ data-end=”139″>Newcastle disease, Infectious Bronchitis, Gumboro (IBD), Marek’s disease, Fowl pox, and Coccidiosis.

They can be prevented by:

-

<strong data-start=”175″ data-end=”199″>Vaccination programs at proper ages.

-

<strong data-start=”221″ data-end=”243″>Strict biosecurity – limit visitors, disinfect regularly.

-

<strong data-start=”288″ data-end=”321″>Clean water and balanced feed to boost immunity.

-

<strong data-start=”346″ data-end=”388″>Good ventilation and litter management to reduce stress and infection risk.

-

<strong data-start=”431″ data-end=”456″>Regular health checks and early isolation of sick birds.Common poultry diseases include Newcastle disease, Infectious Bronchitis, Gumboro (IBD), Marek’s disease, Fowl pox, and Coccidiosis.

They can be prevented by:

Vaccination programs at proper ages.

Strict biosecurity – limit visitors, disinfect regularly.

Clean water and balanced feed to boost immunity.

Good ventilation and litter management to reduce stress and infection risk.

Regular health checks and early isolation of sick birds.

-

-

Thanks for sharing.

-

🌾 – A Simple Tool with Big Impact 🐔

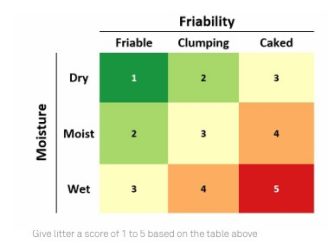

Consistent litter monitoring is crucial for maintaining flock health and performance. A quick and effective way to assess litter is by scoring moisture and friability.

✅ Why it matters:

Detects early issues with drinker systems or ventilation.

Prevents wet litter problems, caking, and ammonia buildup.

Supports better footpad health and bird comfort.

Informs timely management interventions.

📊 Litter Score Guide (1–5):

1 (Ideal) – Dry & friable: free flowing, birds comfortable.

2–3 – Early signs of moisture or clumping: monitor closely.

4–5 (Critical) – Wet or caked litter: increased disease and welfare risks.

📝 Moisture Levels:

Dry: <25% moisture

Moist: 25–35% moisture

Wet: >35% moisture

💡 Friability Check:

Friable → Clumping → Caked (progressive loss of litter quality)

📍 Regular checks under drinker lines and along cool pads help catch problems early before they escalate.

-

To minimize production downtime during maintenance and cleaning:

-

<strong data-start=”71″ data-end=”106″>Schedule preventive maintenance during low-demand or off-peak hours.

-

<strong data-start=”149″ data-end=”184″>Use modular or parallel systems so one line runs while another is cleaned.

-

<strong data-start=”233″ data-end=”266″>Implement quick-clean designs (easy-access panels, CIP systems).

-

<strong data-start=”307″ data-end=”322″>Train staff for efficient maintenance routines and fast changeovers.

-

<strong data-start=”385″ data-end=”422″>Keep critical spare parts on hand to avoid long repair delays.

-

<strong data-start=”457″ data-end=”499″>Plan cleaning and maintenance together to reduce repeated stoppages.To minimize production downtime during maintenance and cleaning:

Schedule preventive maintenance during low-demand or off-peak hours.

Use modular or parallel systems so one line runs while another is cleaned.

Implement quick-clean designs (easy-access panels, CIP systems).

Train staff for efficient maintenance routines and fast changeovers.

Keep critical spare parts on hand to avoid long repair delays.

Plan cleaning and maintenance together to reduce repeated stoppages.

-

-

It includes moisture management, ingredient and pellet quality issues, and nutrient degradation.

-

Mohamed Hamada Nasser

MemberOctober 16, 2025 at 11:31 am in reply to: shrinkage percentage of corn grainsIf corn starts at <strong data-start=”157″ data-end=”180″>15% moisture (w.b.) and dries toward equilibrium under <strong data-start=”216″ data-end=”241″>35–49°C and 60–70% RH, final moisture will typically end up roughly <strong data-start=”288″ data-end=”304″>≈11–13% w.b. depending on exact RH/time. That gives an expected <strong data-start=”356″ data-end=”388″>weight shrinkage ≈ 2.3%–4.5% of the stored grain mass (example calculations below).

<strong data-start=”445″ data-end=”469″>How I calculated it:<br data-start=”469″ data-end=”472″> For 1 kg wet grain with initial moisture <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><msub><mi>M</mi><mi>i</mi></msub></mrow><annotation encoding=”application/x-tex”>M_i</annotation></semantics></math>Mi and final moisture <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><msub><mi>M</mi><mi>f</mi></msub></mrow><annotation encoding=”application/x-tex”>M_f</annotation></semantics></math>Mf (both as decimal wet-basis), final mass = <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><mo stretchy=”false”>(</mo><mn>1</mn><mo>−</mo><msub><mi>M</mi><mi>i</mi></msub><mo stretchy=”false”>)</mo><mi mathvariant=”normal”>/</mi><mo stretchy=”false”>(</mo><mn>1</mn><mo>−</mo><msub><mi>M</mi><mi>f</mi></msub><mo stretchy=”false”>)</mo></mrow><annotation encoding=”application/x-tex”>(1-M_i)/(1-M_f)</annotation></semantics></math>(1−Mi)/(1−Mf).<br data-start=”610″ data-end=”613″> Shrinkage (%) = <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><mstyle displaystyle=”true” scriptlevel=”0″><mfrac><mrow><msub><mi>M</mi><mi>i</mi></msub><mo>−</mo><msub><mi>M</mi><mi>f</mi></msub></mrow><mrow><mn>1</mn><mo>−</mo><msub><mi>M</mi><mi>f</mi></msub></mrow></mfrac></mstyle><mo>×</mo><mn>100</mn></mrow><annotation encoding=”application/x-tex”>\dfrac{M_i-M_f}{1-M_f}\times100</annotation></semantics></math>1−MfMi−Mf×100.

Examples:

<ul data-start=”679″ data-end=”831″>

If <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><msub><mi>M</mi><mi>f</mi></msub><mo>=</mo><mn>13</mn><mi mathvariant=”normal”>%</mi></mrow><annotation encoding=”application/x-tex”>M_f=13\%</annotation></semantics></math>Mf=13%: shrinkage = <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><mo stretchy=”false”>(</mo><mn>15</mn><mo>−</mo><mn>13</mn><mo stretchy=”false”>)</mo><mi mathvariant=”normal”>/</mi><mo stretchy=”false”>(</mo><mn>100</mn><mo>−</mo><mn>13</mn><mo stretchy=”false”>)</mo><mo>=</mo><mn>2</mn><mi mathvariant=”normal”>/</mi><mn>87</mn><mo>=</mo><mn>2.30</mn><mi mathvariant=”normal”>%</mi></mrow><annotation encoding=”application/x-tex”>(15-13)/(100-13)=2/87=2.30\%</annotation></semantics></math>(15−13)/(100−13)=2/87=2.30%.

If <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><msub><mi>M</mi><mi>f</mi></msub><mo>=</mo><mn>12</mn><mi mathvariant=”normal”>%</mi></mrow><annotation encoding=”application/x-tex”>M_f=12\%</annotation></semantics></math>Mf=12%: shrinkage ≈ <strong data-start=”777″ data-end=”786″>3.41%.

If <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><msub><mi>M</mi><mi>f</mi></msub><mo>=</mo><mn>11</mn><mi mathvariant=”normal”>%</mi></mrow><annotation encoding=”application/x-tex”>M_f=11\%</annotation></semantics></math>Mf=11%: shrinkage ≈ <strong data-start=”821″ data-end=”830″>4.49%.

<strong data-start=”833″ data-end=”861″>Practical notes & risks:

<ul data-start=”864″ data-end=”1263″>

High temperature (35–49°C) and moderate–high RH (60–70%) accelerate moisture migration and heating — increases risk of spoilage, insect activity and mycotoxin development even if gross shrinkage seems modest.

Shrinkage happens until the grain reaches its equilibrium moisture content (EMC) for the given temperature & RH — that can take days–weeks depending on silo ventilation and bulk depth.

<strong data-start=”1265″ data-end=”1304″>Recommendations to minimize losses:

<ul data-start=”1307″ data-end=”1663″>

Cool and aerate the silo when outside air is cooler/drier (night-time aeration helps).

Monitor silo temperature and probe moisture at several depths regularly.

Target storage moisture ≤14% on intake for warm climates; the lower the better for long storage.

Remove hotspots, turn or unload if heating is detected; consider drying if necessary.If corn starts at 15% moisture (w.b.) and dries toward equilibrium under 35–49°C and 60–70% RH, final moisture will typically end up roughly ≈11–13% w.b. depending on exact RH/time. That gives an expected weight shrinkage ≈ 2.3%–4.5% of the stored grain mass (example calculations below).

How I calculated it:

For 1 kg wet grain with initial moisture

𝑀

𝑖

M

i

and final moisture

𝑀

𝑓

M

f

(both as decimal wet-basis), final mass =

(

1

−

𝑀

𝑖

)

/

(

1

−

𝑀

𝑓

)

(1−M

i

)/(1−M

f

).

Shrinkage (%) =

𝑀

𝑖

−

𝑀

𝑓

1

−

𝑀

𝑓

×

100

1−M

f

M

i

−M

f

×100.

Examples:

If

𝑀

𝑓

=

13

%

M

f

=13%: shrinkage =

(

15

−

13

)

/

(

100

−

13

)

=

2

/

87

=

2.30

%

(15−13)/(100−13)=2/87=2.30%.If

𝑀

𝑓

=

12

%

M

f

=12%: shrinkage ≈ 3.41%.

If

𝑀

𝑓

=

11

%

M

f

=11%: shrinkage ≈ 4.49%.

Practical notes & risks:

High temperature (35–49°C) and moderate–high RH (60–70%) accelerate moisture migration and heating — increases risk of spoilage, insect activity and mycotoxin development even if gross shrinkage seems modest.

Shrinkage happens until the grain reaches its equilibrium moisture content (EMC) for the given temperature & RH — that can take days–weeks depending on silo ventilation and bulk depth.

Recommendations to minimize losses:

Cool and aerate the silo when outside air is cooler/drier (night-time aeration helps).

Monitor silo temperature and probe moisture at several depths regularly.

Target storage moisture ≤14% on intake for warm climates; the lower the better for long storage.

Remove hotspots, turn or unload if heating is detected; consider drying if necessary.

-

This is good