Dr. Gajanan

MemberForum Replies Created

-

Can give your layer flock the infectious Bronchitis (IB) vaccine ever if they are Mycoplasma synoviae positive.

-

Water pH level 0-14 with 7 being neutral. ORP: (Oxidation-Reduction Potential) a water sample’s ability to break down contaminants and disinfect itself.

-

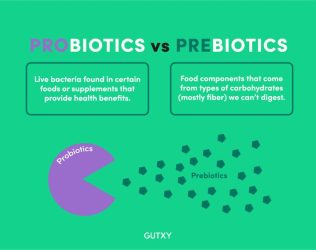

The best time to use probiotics in birds, immediately after hatch and during the first few weeks.

-

Greenish diarrhea is majorly due to ND

-

When is the best time to use probiotics or prebiotics or Phytobiotic ?

-

All grower feed 4-6 mm

All finisher feed 5-7 mm

-

In a feedmill, an alarm system is an important safety and monitoring tool. It helps protect workers, machines, and products by detecting abnormal conditions early and alerting operators. Here are the main uses of an alarm system in a feedmill:

1. Fire and Explosion Safety

- Feedmills handle a lot of dust, which is highly combustible.

- Alarm systems detect smoke, fire, or excessive dust accumulation.

- Early warnings prevent fire outbreaks or dust explosions.

2. Equipment Protection

- Machines like grinders, mixers, and pelletizers can overheat or run under abnormal conditions.

- Alarm systems alert operators when there’s overheating, vibration, or overload, preventing breakdowns and costly repairs.

3. Process Monitoring

- Ensures that production runs smoothly by signaling blockages, low material flow, or abnormal noise in equipment.

- Helps maintain consistent feed quality.

4. Worker Safety

- Alarms warn workers of emergencies such as gas leaks (e.g., CO₂, steam), electrical faults, or mechanical failures.

- Supports quick evacuation and accident prevention.

5. Inventory and Storage Safety

- In silos or warehouses, alarms can detect temperature rise, gas buildup, or pest infestation, which can spoil feed.

- Prevents large-scale feed loss.

6. Energy Efficiency

- By detecting faults early, alarms reduce energy waste from machines running inefficiently.

✅ In summary: An alarm system in a feedmill ensures safety, efficiency, and reliability by providing early warnings for fire, equipment failure, unsafe conditions, and process disruptions.

-

Andrew Toluhi

MemberSeptember 10, 2025 at 11:23 pm in reply to: A simple explanation of the extrusion processAn aquafeed extrusion machine is a machine used to make fish feed pellets. It works like this:

-

Raw materials enter – Ingredients like maize, soybean meal, fish meal, vitamins, minerals, etc., are ground into powder and fed into the machine.

-

Mixing & pre-conditioning – Steam and water may be added to soften and partially cook the powder, making it easier to form pellets.

-

Extrusion (the main process) – Inside the extruder barrel, there’s a screw that pushes the material forward under high temperature, pressure, and friction.

- The heat cooks the feed.

- The pressure compresses it.

-

Die & cutting – The hot, cooked feed is forced through a die (a metal plate with holes) to shape it into pellets. A rotating knife cuts the pellets to size.

-

Expansion & floating – When the pellets come out of the die, the sudden drop in pressure makes them expand.

- If enough starch was gelatinized, the pellets will float (good for fish like catfish or tilapia).

- Less expansion makes sinking pellets (good for shrimp or bottom-feeders).

-

Drying & cooling – The pellets are dried to remove excess moisture and then cooled, so they don’t spoil or break apart.

-

Coating (optional) – Oil, vitamins, or attractants can be sprayed on the pellets after drying to improve nutrition and palatability.

👉 In short: The extruder cooks, shapes, and expands fish feed under heat and pressure, then cuts, dries, and cools it into pellets.

-

-

What exactly should the length of the pellet be?

-

Dr.S.Sridhar

MemberSeptember 11, 2025 at 3:38 am in reply to: Sudden Death Syndrome (SDS) Part -3 RX👍.

-

Dr.S.Sridhar

MemberSeptember 11, 2025 at 3:38 am in reply to: Sudden Death Syndrome (SDS) Part -3 RXThank you.