JOSHUA KWENSIM ANDEZE

MemberForum Replies Created

-

Olayiwola

MemberOctober 16, 2025 at 12:53 pm in reply to: Role & Importance of Smart Sensors, AI, IoT, & Mobile Dashboards in AquacultureThanks for the detailed explanation

-

Thanks, well detailed explanation

-

Excellent, thanks for the explanation

-

Good

Sharing knowledge

-

Nice sharing

-

Common <strong data-start=”7″ data-end=”27″>poultry diseases include <strong data-start=”36″ data-end=”139″>Newcastle disease, Infectious Bronchitis, Gumboro (IBD), Marek’s disease, Fowl pox, and Coccidiosis.

They can be prevented by:

-

<strong data-start=”175″ data-end=”199″>Vaccination programs at proper ages.

-

<strong data-start=”221″ data-end=”243″>Strict biosecurity – limit visitors, disinfect regularly.

-

<strong data-start=”288″ data-end=”321″>Clean water and balanced feed to boost immunity.

-

<strong data-start=”346″ data-end=”388″>Good ventilation and litter management to reduce stress and infection risk.

-

<strong data-start=”431″ data-end=”456″>Regular health checks and early isolation of sick birds.Common poultry diseases include Newcastle disease, Infectious Bronchitis, Gumboro (IBD), Marek’s disease, Fowl pox, and Coccidiosis.

They can be prevented by:

Vaccination programs at proper ages.

Strict biosecurity – limit visitors, disinfect regularly.

Clean water and balanced feed to boost immunity.

Good ventilation and litter management to reduce stress and infection risk.

Regular health checks and early isolation of sick birds.

-

-

Thanks for sharing.

-

🌾 – A Simple Tool with Big Impact 🐔

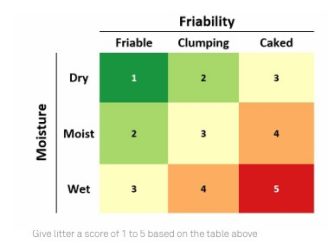

Consistent litter monitoring is crucial for maintaining flock health and performance. A quick and effective way to assess litter is by scoring moisture and friability.

✅ Why it matters:

Detects early issues with drinker systems or ventilation.

Prevents wet litter problems, caking, and ammonia buildup.

Supports better footpad health and bird comfort.

Informs timely management interventions.

📊 Litter Score Guide (1–5):

1 (Ideal) – Dry & friable: free flowing, birds comfortable.

2–3 – Early signs of moisture or clumping: monitor closely.

4–5 (Critical) – Wet or caked litter: increased disease and welfare risks.

📝 Moisture Levels:

Dry: <25% moisture

Moist: 25–35% moisture

Wet: >35% moisture

💡 Friability Check:

Friable → Clumping → Caked (progressive loss of litter quality)

📍 Regular checks under drinker lines and along cool pads help catch problems early before they escalate.

-

To minimize production downtime during maintenance and cleaning:

-

<strong data-start=”71″ data-end=”106″>Schedule preventive maintenance during low-demand or off-peak hours.

-

<strong data-start=”149″ data-end=”184″>Use modular or parallel systems so one line runs while another is cleaned.

-

<strong data-start=”233″ data-end=”266″>Implement quick-clean designs (easy-access panels, CIP systems).

-

<strong data-start=”307″ data-end=”322″>Train staff for efficient maintenance routines and fast changeovers.

-

<strong data-start=”385″ data-end=”422″>Keep critical spare parts on hand to avoid long repair delays.

-

<strong data-start=”457″ data-end=”499″>Plan cleaning and maintenance together to reduce repeated stoppages.To minimize production downtime during maintenance and cleaning:

Schedule preventive maintenance during low-demand or off-peak hours.

Use modular or parallel systems so one line runs while another is cleaned.

Implement quick-clean designs (easy-access panels, CIP systems).

Train staff for efficient maintenance routines and fast changeovers.

Keep critical spare parts on hand to avoid long repair delays.

Plan cleaning and maintenance together to reduce repeated stoppages.

-

-

It includes moisture management, ingredient and pellet quality issues, and nutrient degradation.

-

Mohamed Hamada Nasser

MemberOctober 16, 2025 at 11:31 am in reply to: shrinkage percentage of corn grainsIf corn starts at <strong data-start=”157″ data-end=”180″>15% moisture (w.b.) and dries toward equilibrium under <strong data-start=”216″ data-end=”241″>35–49°C and 60–70% RH, final moisture will typically end up roughly <strong data-start=”288″ data-end=”304″>≈11–13% w.b. depending on exact RH/time. That gives an expected <strong data-start=”356″ data-end=”388″>weight shrinkage ≈ 2.3%–4.5% of the stored grain mass (example calculations below).

<strong data-start=”445″ data-end=”469″>How I calculated it:<br data-start=”469″ data-end=”472″> For 1 kg wet grain with initial moisture <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><msub><mi>M</mi><mi>i</mi></msub></mrow><annotation encoding=”application/x-tex”>M_i</annotation></semantics></math>Mi and final moisture <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><msub><mi>M</mi><mi>f</mi></msub></mrow><annotation encoding=”application/x-tex”>M_f</annotation></semantics></math>Mf (both as decimal wet-basis), final mass = <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><mo stretchy=”false”>(</mo><mn>1</mn><mo>−</mo><msub><mi>M</mi><mi>i</mi></msub><mo stretchy=”false”>)</mo><mi mathvariant=”normal”>/</mi><mo stretchy=”false”>(</mo><mn>1</mn><mo>−</mo><msub><mi>M</mi><mi>f</mi></msub><mo stretchy=”false”>)</mo></mrow><annotation encoding=”application/x-tex”>(1-M_i)/(1-M_f)</annotation></semantics></math>(1−Mi)/(1−Mf).<br data-start=”610″ data-end=”613″> Shrinkage (%) = <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><mstyle displaystyle=”true” scriptlevel=”0″><mfrac><mrow><msub><mi>M</mi><mi>i</mi></msub><mo>−</mo><msub><mi>M</mi><mi>f</mi></msub></mrow><mrow><mn>1</mn><mo>−</mo><msub><mi>M</mi><mi>f</mi></msub></mrow></mfrac></mstyle><mo>×</mo><mn>100</mn></mrow><annotation encoding=”application/x-tex”>\dfrac{M_i-M_f}{1-M_f}\times100</annotation></semantics></math>1−MfMi−Mf×100.

Examples:

<ul data-start=”679″ data-end=”831″>

If <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><msub><mi>M</mi><mi>f</mi></msub><mo>=</mo><mn>13</mn><mi mathvariant=”normal”>%</mi></mrow><annotation encoding=”application/x-tex”>M_f=13\%</annotation></semantics></math>Mf=13%: shrinkage = <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><mo stretchy=”false”>(</mo><mn>15</mn><mo>−</mo><mn>13</mn><mo stretchy=”false”>)</mo><mi mathvariant=”normal”>/</mi><mo stretchy=”false”>(</mo><mn>100</mn><mo>−</mo><mn>13</mn><mo stretchy=”false”>)</mo><mo>=</mo><mn>2</mn><mi mathvariant=”normal”>/</mi><mn>87</mn><mo>=</mo><mn>2.30</mn><mi mathvariant=”normal”>%</mi></mrow><annotation encoding=”application/x-tex”>(15-13)/(100-13)=2/87=2.30\%</annotation></semantics></math>(15−13)/(100−13)=2/87=2.30%.

If <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><msub><mi>M</mi><mi>f</mi></msub><mo>=</mo><mn>12</mn><mi mathvariant=”normal”>%</mi></mrow><annotation encoding=”application/x-tex”>M_f=12\%</annotation></semantics></math>Mf=12%: shrinkage ≈ <strong data-start=”777″ data-end=”786″>3.41%.

If <math xmlns=”http://www.w3.org/1998/Math/MathML”><semantics><mrow><msub><mi>M</mi><mi>f</mi></msub><mo>=</mo><mn>11</mn><mi mathvariant=”normal”>%</mi></mrow><annotation encoding=”application/x-tex”>M_f=11\%</annotation></semantics></math>Mf=11%: shrinkage ≈ <strong data-start=”821″ data-end=”830″>4.49%.

<strong data-start=”833″ data-end=”861″>Practical notes & risks:

<ul data-start=”864″ data-end=”1263″>

High temperature (35–49°C) and moderate–high RH (60–70%) accelerate moisture migration and heating — increases risk of spoilage, insect activity and mycotoxin development even if gross shrinkage seems modest.

Shrinkage happens until the grain reaches its equilibrium moisture content (EMC) for the given temperature & RH — that can take days–weeks depending on silo ventilation and bulk depth.

<strong data-start=”1265″ data-end=”1304″>Recommendations to minimize losses:

<ul data-start=”1307″ data-end=”1663″>

Cool and aerate the silo when outside air is cooler/drier (night-time aeration helps).

Monitor silo temperature and probe moisture at several depths regularly.

Target storage moisture ≤14% on intake for warm climates; the lower the better for long storage.

Remove hotspots, turn or unload if heating is detected; consider drying if necessary.If corn starts at 15% moisture (w.b.) and dries toward equilibrium under 35–49°C and 60–70% RH, final moisture will typically end up roughly ≈11–13% w.b. depending on exact RH/time. That gives an expected weight shrinkage ≈ 2.3%–4.5% of the stored grain mass (example calculations below).

How I calculated it:

For 1 kg wet grain with initial moisture

𝑀

𝑖

M

i

and final moisture

𝑀

𝑓

M

f

(both as decimal wet-basis), final mass =

(

1

−

𝑀

𝑖

)

/

(

1

−

𝑀

𝑓

)

(1−M

i

)/(1−M

f

).

Shrinkage (%) =

𝑀

𝑖

−

𝑀

𝑓

1

−

𝑀

𝑓

×

100

1−M

f

M

i

−M

f

×100.

Examples:

If

𝑀

𝑓

=

13

%

M

f

=13%: shrinkage =

(

15

−

13

)

/

(

100

−

13

)

=

2

/

87

=

2.30

%

(15−13)/(100−13)=2/87=2.30%.If

𝑀

𝑓

=

12

%

M

f

=12%: shrinkage ≈ 3.41%.

If

𝑀

𝑓

=

11

%

M

f

=11%: shrinkage ≈ 4.49%.

Practical notes & risks:

High temperature (35–49°C) and moderate–high RH (60–70%) accelerate moisture migration and heating — increases risk of spoilage, insect activity and mycotoxin development even if gross shrinkage seems modest.

Shrinkage happens until the grain reaches its equilibrium moisture content (EMC) for the given temperature & RH — that can take days–weeks depending on silo ventilation and bulk depth.

Recommendations to minimize losses:

Cool and aerate the silo when outside air is cooler/drier (night-time aeration helps).

Monitor silo temperature and probe moisture at several depths regularly.

Target storage moisture ≤14% on intake for warm climates; the lower the better for long storage.

Remove hotspots, turn or unload if heating is detected; consider drying if necessary.

-

It includes <mark>moisture management, ingredient and pellet quality issues, and nutrient degradation</mark>.

-

It’s highly appreciated

-

3-4 hours interval between feeding increase Digestion, growth and FCR