Sharad

MemberForum Replies Created

-

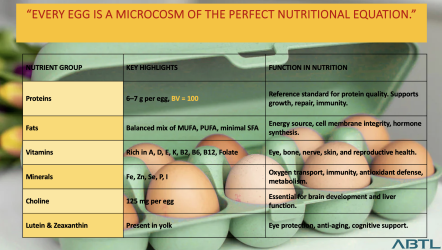

On 10th of October we celebrated egg!

The richness, the nutritional attributes and the eggciting wonders that it can do in by passing malnutrition in developing Asian and African countries. Here is a glimpse of egg nutrition in a go!

-

Udumula Kranthi kumar

MemberOctober 14, 2025 at 4:20 am in reply to: Moisture & Aeration Management at SiloTo remove moisture from grains, natural drying is definitely not the best method: too long times, risks of product loss and uneven drying make this process almost counterproductive. Much more advantageous is to use grain dryers – mobile or tower – which allow optimal and rapid drying

-

Rotimi

MemberOctober 13, 2025 at 10:44 pm in reply to: Role & Importance of Smart Sensors, AI, IoT, & Mobile Dashboards in AquacultureSmart sensors, AI, IoT, and mobile dashboards play crucial roles in aquaculture, transforming the industry’s efficiency, sustainability, and productivity. Here are their key roles and importance:

*Smart Sensors:*

– *Real-time monitoring*: Track water quality parameters like temperature, pH, and dissolved oxygen levels.

– *Early detection*: Identify changes in environmental parameters, enabling prompt action to prevent diseases and maintain optimal conditions.

– *Data collection*: Provide accurate and reliable data for informed decision-making.

*AI (Artificial Intelligence):*

– *Predictive analytics*: Analyze historical data and current trends to predict future outcomes, such as growth rates, feed requirements, and potential disease risks.

– *Disease detection*: Identify early signs of diseases or health issues in fish, enabling timely interventions.

– *Feed optimization*: Determine optimal feeding strategies based on fish growth, feed intake, and environmental conditions.

*IoT (Internet of Things):*

– *Remote monitoring*: Enable farmers to monitor and control aquaculture operations remotely, reducing the need for on-site visits.

– *Data transmission*: Facilitate real-time data transmission from sensors to cloud platforms for analysis and decision-making.

– *Automation*: Integrate with automation systems to optimize water quality parameters, feeding schedules, and other operational aspects.

*Mobile Dashboards:*

– *Real-time insights*: Provide farmers with real-time insights into aquaculture operations, enabling informed decision-making.

– *Remote access*: Allow farmers to access and manage aquaculture operations from anywhere, at any time.

– *Timely alerts*: Send notifications and alerts to farmers about potential issues, ensuring prompt action.

The importance of these technologies in aquaculture includes:

– *Improved productivity*: Optimized feeding strategies, better water quality management, and reduced disease outbreaks contribute to increased productivity.

– *Sustainability*: Efficient resource utilization, reduced waste, and improved environmental management promote sustainable aquaculture practices.

– *Cost savings*: Reduced feed waste, improved feed conversion ratios, and optimized energy consumption lead to cost savings.

– *Enhanced decision-making*: Data-driven insights enable farmers to make informed decisions, reducing the risk of errors and improving overall efficiency.Smart sensors, AI, IoT, and mobile dashboards play crucial roles in aquaculture, transforming the industry’s efficiency, sustainability, and productivity. Here are their key roles and importance:

*Smart Sensors:*

– *Real-time monitoring*: Track water quality parameters like temperature, pH, and dissolved oxygen levels.

– *Early detection*: Identify changes in environmental parameters, enabling prompt action to prevent diseases and maintain optimal conditions.

– *Data collection*: Provide accurate and reliable data for informed decision-making.*AI (Artificial Intelligence):*

– *Predictive analytics*: Analyze historical data and current trends to predict future outcomes, such as growth rates, feed requirements, and potential disease risks.

– *Disease detection*: Identify early signs of diseases or health issues in fish, enabling timely interventions.

– *Feed optimization*: Determine optimal feeding strategies based on fish growth, feed intake, and environmental conditions.*IoT (Internet of Things):*

– *Remote monitoring*: Enable farmers to monitor and control aquaculture operations remotely, reducing the need for on-site visits.

– *Data transmission*: Facilitate real-time data transmission from sensors to cloud platforms for analysis and decision-making.

– *Automation*: Integrate with automation systems to optimize water quality parameters, feeding schedules, and other operational aspects.*Mobile Dashboards:*

– *Real-time insights*: Provide farmers with real-time insights into aquaculture operations, enabling informed decision-making.

– *Remote access*: Allow farmers to access and manage aquaculture operations from anywhere, at any time.

– *Timely alerts*: Send notifications and alerts to farmers about potential issues, ensuring prompt action.The importance of these technologies in aquaculture includes¹ ² ³:

– *Improved productivity*: Optimized feeding strategies, better water quality management, and reduced disease outbreaks contribute to increased productivity.

– *Sustainability*: Efficient resource utilization, reduced waste, and improved environmental management promote sustainable aquaculture practices.

– *Cost savings*: Reduced feed waste, improved feed conversion ratios, and optimized energy consumption lead to cost savings.

– *Enhanced decision-making*: Data-driven insights enable farmers to make informed decisions, reducing the risk of errors and improving overall efficiency. -

For maize silos, feed mills follow aeration practices that focus on cooling, drying, and preventing spoilage by using fans to move air through the grain at specific times. Key practices include cleaning the grain before storage, ensuring uniform grain distribution in the silo, and aerating when ambient humidity is low to maintain a grain temperature between 2 °C and 10°C to reduce mold and pest growth. Advanced systems may use humidity and temperature sensors with automated fan controls, and some facilities operate the fans for short, timed cycles (e.g., 10-15 minutes every 2-3 hours) to allow air to reach equilibrium after fumigation

-

For industrial or large-scale poultry sheds, spray foam insulation offers superior, gap-filling, and quick installation, while fiberglass batts are a cost-effective and durable option for new construction. For smaller coops or do-it-yourself projects, rigid foam boards are effective and easier to install, though can be difficult to cut.

-

The best way to insulate is , thermocol sheets in control houses .

In open houses you can use varieties of thing , like mud with rice straws etc..

-

what are best methods to insulate the roof and walls of poultry house/shed?

-

Maintaining a throw sieve (also known as a vibrating sieve or rotary sifter) in a feedmill is essential for ensuring efficient separation of materials, consistent product quality, and smooth equipment operation. Here are key ways to maintain a throw sieve in a feedmill:

<hr>

🔧 1. Regular Cleaning- Daily Cleaning: Remove any buildup of material on the screen and frame.

- Prevent Clogging: Check for particles stuck in the mesh and use brushes or compressed air (if safe).

- Avoid Moisture: Ensure the sieve and surrounding area are dry to prevent caking or corrosion.

<hr>

🔍 2. Routine Inspection- Screen Mesh Condition: Look for tears, holes, or sagging mesh. Replace if damaged.

- Rubber Balls or Cleaners: Ensure they are in good condition and not hardened or missing.

- Gaskets & Seals: Inspect for wear or cracking that may cause leaks or contamination.

- Fasteners: Tighten loose bolts, nuts, and clamps to avoid vibrations or misalignment.

<hr>

⚙️ 3. Check Mechanical Components- Vibration Motor: Inspect for unusual noise or overheating. Ensure it’s mounted securely.

- Bearings: Lubricate as per manufacturer specs. Replace if worn or noisy.

- Drive Belt/Linkage: Ensure proper tension and alignment. Replace worn belts.

<hr>

📏 4. Ensure Proper Alignment and Balancing- Misalignment can lead to inefficient sieving and mechanical failure.

- Check balance weights and vibration settings regularly.

<hr>

🧰 5. Use Correct Screen Size and Material- Match screen mesh size to material being processed.

- Use durable mesh materials (e.g., stainless steel) for abrasive feeds.

<hr>

🗓️ 6. Establish a Maintenance Schedule- Create a preventive maintenance checklist.

- Assign routine tasks daily, weekly, and monthly.

- Keep maintenance records to track recurring issues.

<hr>

⚠️ 7. Operator Training- Ensure operators understand proper use, loading limits, and signs of malfunction.

- Train them to shut down equipment if abnormalities occur.

<hr>

🔒 8. Safety Measures- Always lock out/tag out before performing maintenance.

- Use protective gear when cleaning or inspecting machinery.

<hr>

-

Olayiwola

MemberOctober 13, 2025 at 4:50 pm in reply to: SEC Nigeria, Sub-Saharan Africa Poultry Management (Basic Certificate) Cohort #6Great insight

-

<b data-start=”242″ data-end=”283″><strong data-start=”248″ data-end=”283″>Provide Adequate Ventilation

<ul data-start=”284″ data-end=”514″>

Ensure <strong data-start=”293″ data-end=”316″>strong air movement inside the shed.

Use <strong data-start=”342″ data-end=”358″>exhaust fans or <strong data-start=”362″ data-end=”384″>tunnel ventilation to remove hot air.

Keep <strong data-start=”413″ data-end=”432″>air inlets open for proper circulation.

Avoid blocking airflow with feed bags or equipment.

-

Ventilation is a critical aspect of broiler poultry production, as it directly affects bird health, growth performance, and overall productivity. Proper ventilation ensures a continuous supply of fresh air while removing excess heat, moisture, dust, and harmful gases such as ammonia and carbon dioxide from the poultry house. It helps maintain the desired temperature, humidity, and air quality, which are essential for efficient feed conversion and reduced mortality. There are two main types of ventilation systems: natural ventilation, which relies on wind and side openings, and mechanical ventilation, which uses fans and air inlets to control airflow.