Lina Paola Pardo Quevedo

MemberForum Replies Created

-

Dr.S.Sridhar

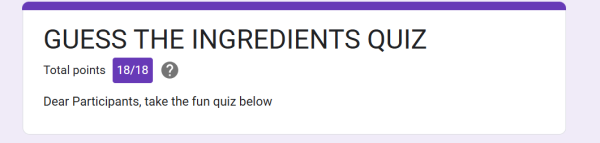

MemberSeptember 6, 2025 at 3:04 am in reply to: A Quick Quiz on Common Salts in Poultry Nutrition📢 Poultry Quiz Alert! J A Quick on Common Salt in Poultry Nutrition. Let’s test your know-how and sharpen field insights.

A quiz on usage of common salt like Nacl, Kcl in poultry ration

https://forms.gle/fGa9CehQMN8jMz4YA

Comment 👍🏼 if answered.

-

In addition, each mill is configured to achieve certain tonnage when running optimally. In all cases, the component of the mill ( mixer, hammermill, etc) are optimised to have the capacity to achieve the target tonnage. This tonnage can be 20mt/hour , 40mt/hour etc.

-

<font dir=”auto” style=”vertical-align: inherit;”><font dir=”auto” style=”vertical-align: inherit;”>Uno de los factores más importantes que determinan la velocidad de corte es la dureza del material que se corta. Cuanto más duro es el material, más lenta es la velocidad de corte y viceversa. Por ejemplo, el mecanizado de materiales como el acero requerirá una velocidad de corte más baja en comparación con el aluminio.</font></font>

<font dir=”auto” style=”vertical-align: inherit;”><font dir=”auto” style=”vertical-align: inherit;”>La velocidad de corte (o “fresado de velocidad”) se refiere a la rapidez con la que la herramienta gira para cortar el material (medida en metros por minuto o pies por minuto), mientras que la velocidad de avance (o “fresado de avance”) se refiere a la rapidez con la que la herramienta avanza linealmente a través de la pieza de trabajo (medida en milímetros por revolución o pulgadas por revolución)</font></font>

-

The only operational advantage I can think of is that a double stand may allow for larger pellets to be produced thus increasing feed production – with the double stand the top pair would be set to provide a slightly reduced size, with the second pair set to complete the reduction to the desired finished size. If using a single pair crumbler the rolls must be adjusted to accepted the pellets without grinding them, which leads to fines generation, thus you may need to use a smaller diameter pellet die which will reduce feed production per hour. Also the need to change pellet dies leads to ‘down time’ resulting in decreased production rate.

-

Dr. Pardhu

MemberSeptember 5, 2025 at 2:51 pm in reply to: Discussion – How to make it more useful for individual and everyone within groupGood idea

-

Digestive, Respiratory and Reproductive diseases.

-

-

Bioavailability of a substance or nutrient is the ability to 100% absorb and assimilate in the body.

-

RAHUL

MemberSeptember 5, 2025 at 5:52 am in reply to: Discussion Group Rules – PLEASE REVIEW AND ADHERE!Noted!

-

Feeding schedule rearrange & improve ventilation system.

-

ASIA has done excellent job of presenting and explaining mixing – he is correct in saying there is not ‘one’ correct mixing time as mixers operate differently, feed compounding uses diverse ingredients (both dry and liquid). Always remember that the mixer is what controls the rate at which feed is manufactured – CVs of 10% or less may require more or less time depending on ingredients AND if using liquids always factor in the extra time allotted after dry mix is complete.

-

In Feed manufacturing ‘feed’ speed refers to the rate at which material is introduced into a processing machine such as a hammer or roller mill, a pellet press conditioner or other processing machine where feed rate is an important variable to control. In particle size reduction the ‘tip speed’ of the hammers is governed by the rotational speed of the shaft driving the rotors from which the hammers are suspended and tip speed is determined using a math formula. Sometimes hammermill motors are equipped with a Variable Frequency Drive (VFD) which allows for changes to the rotational speed of the shaft.

The terms have nothing to do with industrial milling.